The business of 3D printers is a lot bigger than that of the Internet. It uses modern technology, which is a big part of why people like it. But many people still don’t know how 3D printing works, so they can’t use it in their business. So, we’ll discuss what 3D printing is and how it works in this article. We will also discuss the essential procedures for making something with a 3D printer.

What is 3D Printing?

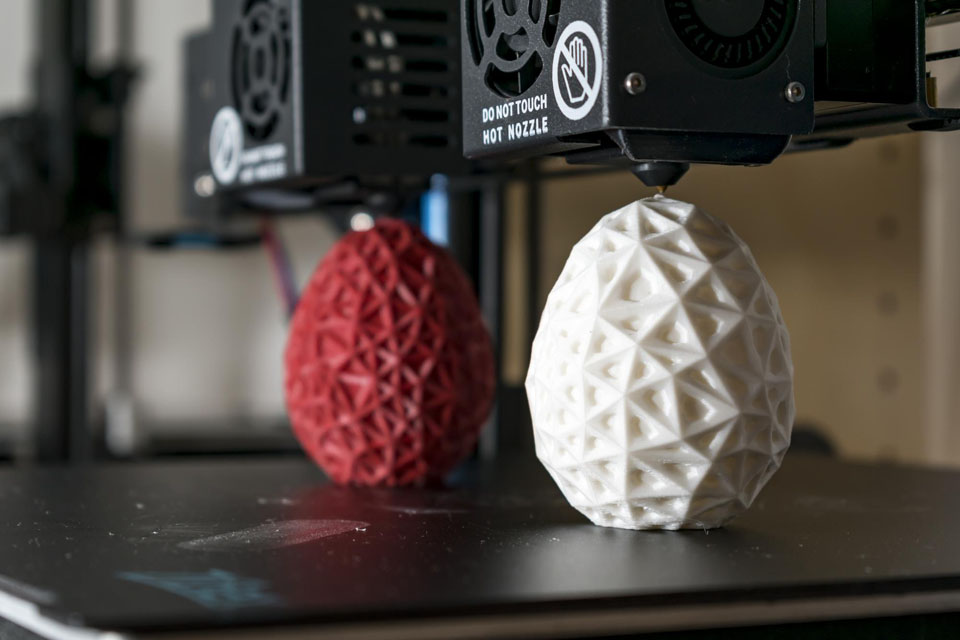

Simply put, it is a way to make a 3D object from a CAD model. It is also called “Additive Printing” because the printing is done by putting layers on each other. In 1990, businesses started using this technology to make prototypes. Slowly, people started to understand what significance this process was. Now, 3D printing can be utilized to make things that are very hard to make.

What type of science is 3D printing built on?

The main ideas behind 3D printing are using computer models and adding layers to make new shapes. Different 3D printers use different kinds of technology and materials. Still, the main idea stays the same. With the assistance of a heat source, the printer will take writing material and melt it.

The wet material will then be sent to the tip of the extruder, turning it into thin strands. The computer knows where to put these strands because of the CAD model on the computer. Strand casting is a process that is repeated until the final shape of the end item is reached.

What Can a 3D Printer Produce?

If there is a picture of the item on a computer, a 3D printer can make almost anything. It can make things faster than most manufacturing units, and nothing else can also make things. It can also make parts that are hard to make by hand or using other tools.

Different types of 3D printers

The two most well-known kinds of 3D printers are:

Fused Deposition Modelling (FDM)

This is how to use a filament spool to make something from a 3D CAD model. The material comes from the tip when the printer heats it to a certain temperature. The machine sets a line, and the sprayer puts down several coats along that line. This process keeps going until the thing reaches its final shape. Check out the FDM 3D Printing Guide, which was put together by our team.

Stereolithography

This is the first kind of 3D printing. Because it is an old machine, it prints with a mirror. With the help of a mirror, the machine sends the laser back to the material to melt and harden it exactly where it needs to be. You can look at our team’s guide about SLA 3D printing.

Digital Light Processing

This is a better version of Stereolithography than the first one. It replaced the hand-placed mirrors and used a precise tool to make the printing process more accurate.

Printing Material

Since there are different types of 3D printers, it makes sense that they have many different materials.

Polylactic Acid (PLA)

It naturally breaks down because it comes from sugarcane or cornstarch. It also has a nice smell and holds things well. This material is soft and easily made into nearly any form you want. It gets warm at a very low temperature, so it can be used to print at 190 degrees Celsius.

Acrylonitrile Butadiene Styrene (ABS)

It is the material used to make Lego blocks. It does not break down worldwide because it is made from fossil fuels. It smells like burned plastic when it’s written. It is a bit hard because it is made of tough plastics. So, it will take more heat to shape it, but once it is made, it will last for a long time. At 230 degrees Celsius, it gets up to 260 degrees Celsius.

How a 3D printer works

Different types of printers work in different ways and use different materials. But the basic steps for printing remain the same, no matter what kind of printer you have.

- You must make or find the 3D model for the item you want to print.

- Now you’ll need to make an STL file from the 3D model.

- Then you must run the Slicer program to change the STL file format into G-Code.

- In the end, this G-code will be used to print the model.

Conclusion

3D printing is one of the most effective ways to make it. There are some things that 3D printers can’t make. So, we can say that 3D printing has a bright future in business. For instance, 3D printing is crucial to defense and medical research businesses. With this cool technology, things that were once hard to make by hand can be made.